We here at AEIG can fully facilitate all your customer need’s from a basic 2000hr routine maintenance right the way through to full major servicing.

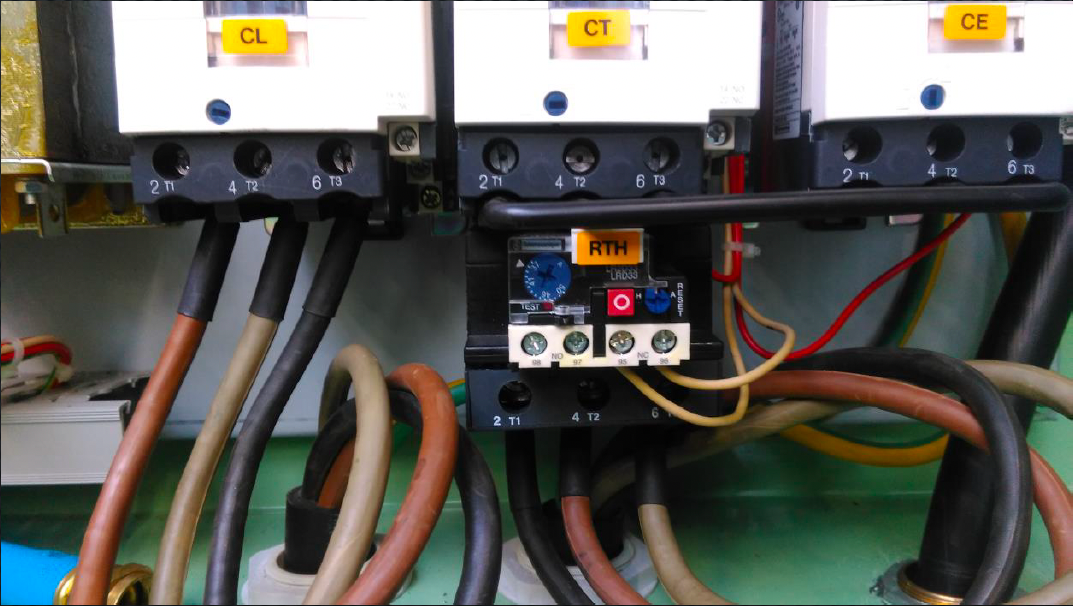

Here at AEIG we pride our selves with having the knowledge and expertise to carry out full in depth investigation’s, taking the time and effort to ensure that we diagnose your equipment’s faults RIGHT THE FIRST TIME.

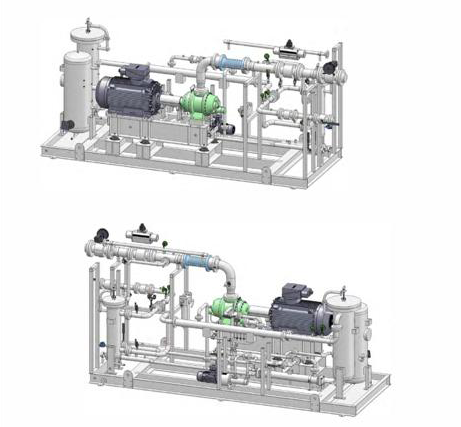

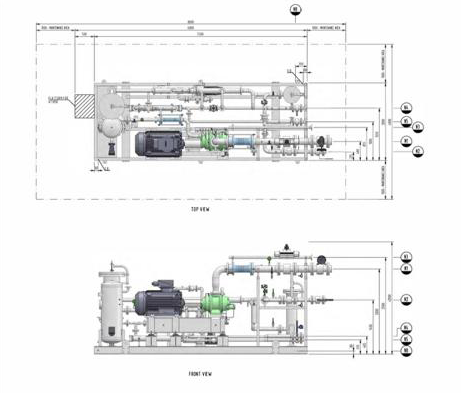

With over 20 year’s of experience in the compressed air industry, specializing in Sullair and ancillary equipment. We have the tools and knowledge to fully maintain, service, repair, overhaul, and custom build various piece’s of equipment to suit a wide verity of applications within all type’s of industries. These industries range from pharmaceutical right the way through to your oil and gas industry.

We here at AEIG are here to offer the highest quality of service, with none of the cutting corners and quick fixes to solve a issue as this attitude will not get the RIGHT THE FIRST TIME results.